This subchapter will zoom in in the subsystems of: aquaculture, worm farming, mushroom cultivation, biodigester and the new transport system that they require. The subsystems of cattle breeding and agriculture are not elaborated on since these subsystems are not the renewed components of the system. The five subsystems will first be described by explaining the technology behind it, thereafter the actors related to the subsystem will be described followed by appointing their needs. The method of YUPTA analysis is used in the actor analysis. The explanation of this method can be found here: link

5.3.1 Aquaculture

Technology for aquaculture:

Research for creating optimal conditions for aquaponics is still on-ongoing. This also makes it hard to estimate how much fish and nutrition is needed to keep the ecosystem in balance. It also depends on the types of fish and types of plants. Therefore it is hard to make a technology roadmap from 2020 to 2065. Texel is known for its research on marine life. This aquaculture facility could be an expansion of current research institutions on Texel.

Actors related to aquaculture:

The aquaculture subsystem has two key actors: NIOZ and Ecomare. These two actors are described below.

NIOZ

NIOZ is an oceanographic institute for the Netherlands. Its mission is to obtain and distribute knowledge about seas and oceans for a sustainable future for our planet. It supports research and education to marine science in the Netherlands and Europe (NIOZ, 2014).

Currently NIOZ does no research to aquaponics. However in 2013 it cooperated with the University of Maastricht, Wageningen, Utrecht and the research institute Carmabi on Curacao to analyze the role of sponges for reusing waste of coral and algae. As stated in the article, this research was important to understand the coral reef and how an ecosystem can be productive without energy loss. It was an important step for the evolution of sustainable forms of aquaculture and sea farming (NIOZ, 2013).

Recently NIOZ opened the Seaweed center, where different types of seaweed are analyzed since seaweed can be used as source of energy (sugars) and food for humans/animals. Cultivation of seaweed can contribute to the transition of a bio based economy (NIOZ, 2014).

Aquaponics is about creating a sustainable eco-system for food production, were plants and fish are being cultivated. Analyzing sea life and mimicking this in aquaponics could be a solution to find sustainable food production. Using the research of the seaweed center can contribute to create a better aquaponics system. It is therefore likely that NIOZ might be interested in starting an aquaponics project in cooperation with partners. The bio-digester can be used directly to provide nutrition for the growth of seaweed.

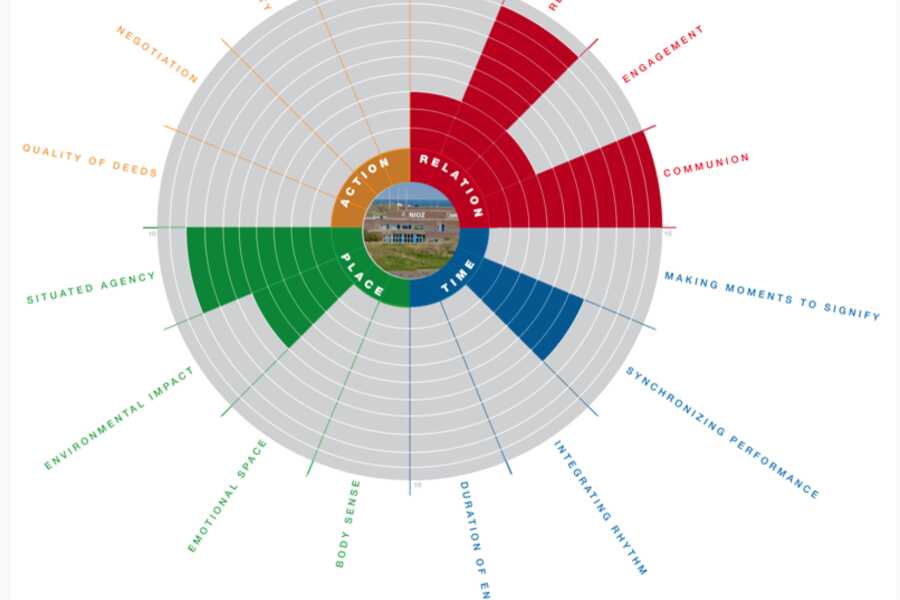

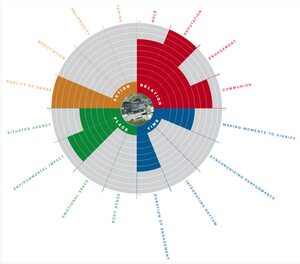

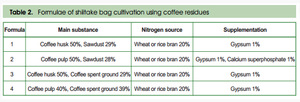

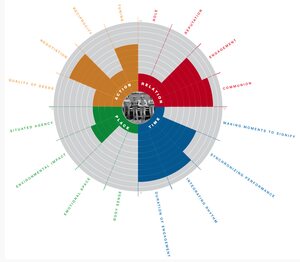

Figure 5.3 YUPTA of NIOZ

NIOZ needs to cooperate with other partners. Since they can also depend on partners their role and engagement is been given a three. Since NIOZ is the oceanographic institute for the Netherlands it has to keep its reputation high. It is highly likely that NIOZ and all partners have the same goal: Obtaining knowledge and distributing knowledge about seas and oceans for a sustainable future for our planet.

Working with partners asks for synchronizing performance. Each partner has to exchange knowledge in order to work together effectively. NIOZ can mean a lot to the other stakeholders, since they have a lot of knowledge on the sea and oceans ecosystems, which can be used in aquaponics. Situated agency is therefore estimated high.

Ecomare

Ecomare stands for keeping and recovering natural values in the ‘Wadden’ and Nord sea. Through education and creating awareness they try to protect the natural habitat. An aquaponics center could educate visitors on aquaculture and natural eco-systems, making it interesting for Ecomare to start an aquaponics center. Since Ecomare is not a research institute it should cooperate with researchers to create optimal conditions for aquaponics.

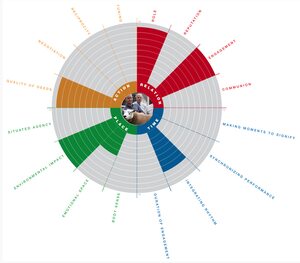

Ecomare can offer an aquaponics facility for research purposes to other institutes, while at the same time using this facility as a tourist attraction. Although the goal of the research institutes might be obtaining knowledge, Ecomare wants to distribute this knowledge, which makes the goals comparable. Since the facility will become a tourist attraction in this case, making moments to signify scores high. Ecomare needs to synchronize performances with the research institutes to create effective relationships. Rhythms need to be integrated by setting clear rules on when the facility is open for visiting hours and when it is closed so research institutes can do their research.

Figure 5.4 YUPTA of Ecomare with regards to Aquaponics

Identified Needs:

The subsystem of aquaculture has several needs in order to be successful.

- The most important need is collaboration between multiple actors (Ecomare and NIOZ, but also tourism companies and the municipality). It is needed that they synchronize their performances.

- An investment is needed in order to build an aquaponics facility. Therefore a good business model has to be written.

5.3.2 Worm Farming

Technology for worm farming:

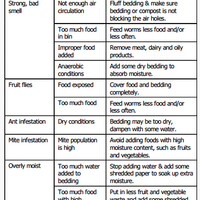

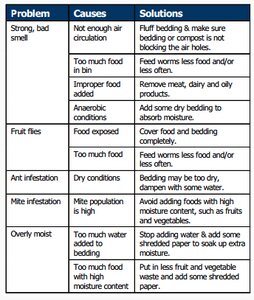

There is no worm farming facility on Texel available yet. Technology to create a worm farm already exists by using worm composting containers and could therefore already be implemented in 2020. Worm farming requires knowledge about nutrients for worms. Fruits and vegetable scraps, egg shells, shredded paper products, fallen leaves, tea bags, coffee ground, lawn clippings and weeds are all suitable. Meat, dairy and oily products are not suitable as feeding for worms, as well as onions, garlic, citrus fruits and large quantities of bread. A right balance of organic material, moisture and air is needed for a successful worm farm environment. Table 5.1 shows indicators for possible problems you can face in worm farming (Logan city council, unknown).

A bio-filter of worms to cleanse water also already exists but may require more investments. Since it is a relative new technology it is better to implement this in 2030 to let this technology develop further before implementing it on Texel.

Table 5.1 Problems with worm farming

Actor analysis:

For the actors there are two options. Option one is that Ecomare opens the worm farming facility, option two is that the worm farming facility is spread among several farmers.

Ecomare

Ecomare stands for keeping and recovering natural values in the ‘Wadden’ and Nordsea. It has a nature museum, seal-nursery, sea-aquarium, bird shelter, dune park and visitor center. Through education and creating awareness they try to protect the natural habitat.

Ecomare has 300.000 visitors a year, which makes them one of the top 10 museums of the Netherlands. The core values of Ecomare are: nature of ‘Wadden’ and Nordsea, experience, knowledge, awareness and inspiration. By translation stories to excursions, exposition, education and web information Ecomare tries to spread knowledge about nature to different target groups (Ecomare, 2007).

Ecomare sees their slow transition to new expositions as a weakness. This while, 40% of the visitors have already visited Ecomare before. Ecomare sees opportunities in creating a facility that revolves about experience and fun. Ecomare wants to move away from the ‘geitenwollensokken’ image and wants to fascinate people from urban areas with the beauty of nature. Visitors of Ecomare come for the animals, therefore Ecomare want to include more animals in their stories and create more stories around animals (Ecomare, 2007). Another weakness Ecomare mentions is the non-oriented-business approach of some projects.

The worm farming facility can be a gate to talk about the importance of worms to the ‘Wadden’. Different types of worm species transform waste into resources for different types of land. In the sea worms digest plankton, waste and small animals into resources. Since worms are part of the food chain for animals and fish, worms are essential for the two main animals Ecomare focusses on and has shelters for. It leads to an opportunity for a new exposition or excursion to give more knowledge on ecosystems. A bio-filter of worms can filter water, which can represent the eco-system in the sea and gives the opportunity to spread more knowledge through this example.

Through worm farming Ecomare is linked to aquaponics. During composting the worms fatten. These fattened worms can be fed to fish. In this way Ecomare can play an essential role in explaining aquaculture. To create a business aspect, the compost can be sold to farmers to maintain land on the Wadden, which can be used again to invest in Ecomare.

Since Ecomare is a tourist attraction, reputation is important. Expanding with a worm farm gives the opportunity to distribute more knowledge on eco-systems and contribute to a self-supportive Texel. Since the worm farming facility becomes a tourist attraction, making moments to signify becomes important. To provide a constant stream of compost and fattened worms for aquaculture, duration of engagement is important as well. The worms could even be fed to the birds of the bird shelter. Depending on the quality of the worm farming, Ecomare is able to make a positive contribution to creating a self-supportive Texel making quality of deeds important.

Figure 5.5 YUPTA of Ecomare regarding the worm farming

Farmers

Since worm farming is possible on small scale as well, farmers could create their own worm composting bin. The compost they generate can be used on their own land directly. The water they filter with a worm biofilter can be used for irrigation of the land or water for the cattle. The problem is that they need sufficient investments to purchase a biofilter and worm container. The large amount of organic waste of restaurants and households can be distributed for free to the farmers as well. The problem with this is that you need transport to deliver the waste to different farmers, while with Ecomare there is one central point the waste can be distributed to.

In this case, the waste of the farmer, becomes a resource for the farmer himself. Since there is a direct benefit it is more likely that the farmer will be engaged. The farmer will need more knowledge about nutrients of worms and needs to add this extra activity to his/her schedule in return of free compost. The environmental impact is huge, since compost fertilizers their own land again. Since farmers are more connected with their land and cattle, the worm farming can go along with emotions since the worm farming allows the farmer to become more self-sufficient and be more in balance with nature.

Figure 5.6 YUPTA of the Farmers regarding worm farming

Identified Needs:

- A first investment is needed in order to set up small or large worm farming facilities. Since worm farming gives direct benefits to the owner, and the investment is rather low, it is expected that the owner (farmer or Ecomare) can pay for the investment themselves.

- Estimate available organic waste (GFT) for worm farming:

In 2012 there was 1983 tons of GFT waste (Gemeente Texel, 2012). Compost worms can eat half of their body weight (Food know how, 2014). A 1000 worms weigh 1lb, which is 0.45kg. This is 0,45g per worm, meaning a worm can digest 0,225g of waste a day. This is 82g a year for which you need 24.182.927 worms. This seems a lot, but red worms reproduce when they reach maturity after 90 days. After that they produce 20 juvenile worms each week in ideal conditions (Batchelder, Unknown). Quickly calculated this means you can have 1000*20*20*20*20= 160.000.000 worms in one year, which is sufficient and also gives room to use the fattened worms as feeding for fish or birds.

5.3.3 Mushroom cultivation center

Technology for mushroom cultivation center:

In order to grow mushrooms on coffee waste you need certain circumstances. In traditional cultivation methods you need bacterial control at high costs, but since the coffee ground is exposed to hot water, bacteria are already reduced to a minimum. Farming mushrooms on coffee spent is 80% more energy efficient than preparing substrates to grow mushrooms on, since it uses free energy needed to prepare the coffee (Pauli, 2010).

Although there are companies that grow mushrooms on coffee, the ideal circumstances are often kept secret from public. Rotterzwam offers an internship of 1 week for 750 euro’s to learn about cultivation methods and growth conditions to prevent other entrepreneurs to make the mistakes they made in the past. It took Rotterzwam 8 months to figure out the ideal conditions through trial and error (Rotterzwam, 2014).

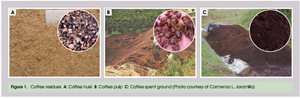

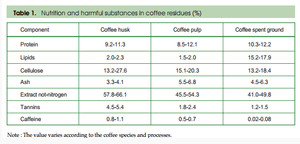

Figure 5.7 Different types of coffee residues

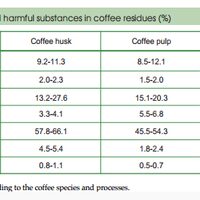

There are different types of coffee residues, which each have their own nutrition and harmful substances. Coffee husk and pulp contain large amounts caffeine and tannins which are harmful for mushroom and inhibit growth of mycelium. Spent coffee grounds are therefore the best type of residue and do not require caffeine removal.

Table 5.2 Growing conditions for oyster mushrooms

Growing conditions for oyster mushrooms:

According to growveg.com you need 500g of oyster mushroom spawn to each 2.5kg of spent coffee ground. At every growing state different circumstance are needed. To prevent mold spores from getting in, which can damage the harvest, fresh coffee ground needs to be used. In the first stage the mushroom spawn with coffee ground needs to be placed in a dark room with 18C-25C degrees. After three weeks the coffee and spawn mixture has become white. If it has become green, molds have been able to grow and the mixture should be thrown away. When the mixture is completely white, it must be placed on a place with fresh air and little light, like a worktop. Twice a day, the area needs to be sprayed with water to prevent the oyster mushrooms from drying out. Damp and humid conditions stimulate growth off mushroom. Therefore often swimming pools or saunas are used for growing mushrooms, like Rotterzwam uses the tenantless swimming pool Tropicana in Rotterdam. A week later, little mushrooms will arise which will double in size every week (Sayner, 2012).

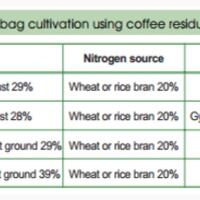

Growing conditions for shiitake mushrooms:

To grow shiitake mushrooms, coffee residues are often mixed with additional cellulosic substrates such as sawdust and rice or wheat to create a desirable texture. Mixture formulas can be found in the figure below. For shiitake 0.3 kg to 0.5 kg can be harvested from 1kg dried substrate. The containers with the mixture should be sterilized at 95 degrees for 9 to 10 hours. Once the spawn is added, the containers/bags with the mixture and spawn should be carried to the fruiting house once the white mycelium covers the full surface. Here the shiitake mushroom can grow and can be watered directly once the bodies have grown 2 cm in diameter (Fan, 2005).

Table 5.3 Growing conditions for Shiitake mushrooms

Technology needed for controlling the environment:

To start a batch you need fresh coffee residual to prevent molds from coming in. Temperature and light control is needed to adapt circumstances to each growing phase. Humidity control and an irrigation system are needed to water the mushrooms, once they have grown. This makes old swimming pools are sauna’s the ideal place to start. Since all technology for cultivation of mushrooms on coffee waste already exists, this part of the design can already be implemented in 2020.

Actors related to mushroom cultivation center:

Two actors are described below: The Texelse Paddelstoelenkwekerij and the hospitality industry:

Texelse Paddenstoelenkwekerij

The ‘Texelse Paddestoelenkwekerij’ offers daily tours at 16.30 pm. Here shiitake mushrooms are cultivated through craftsmanship in a cultivation barn on Texel’s countryside with manual cultivation. Maarten Dijker founded the company in 2008 and cultivates shiitake mushrooms throughout the whole year (VVV, 2014). Currently he uses sawdust, Oakwood, water and spores in order to grow shiitake mushrooms. The mushrooms are cultivated in a closed room, which is kept at a constant temperature. Oakwood is sterilized, spawn is added, and the mixture is put in plastic bags for 8 weeks. After 15 weeks the full grown mushrooms can be harvested (VVV, 2014).

The ‘Texelse Paddestoelenkwekerij’ already has a fixed network of restaurants that make dishes of shiitake mushrooms, which are spread on the island as the map suggests (Texelse Paddestoelenkwekerij, 2011). Maarten Dijker is known on Texel as a local food producer who receives attention at culinary cooking fairs and tourist attractions. Shiitake mushrooms can be baked with olive oil, used in soup or sauces, baked with fish, lam, beef and hearty cake, which is seen as local Texel cooking (Texelvakantietv, 2011). Maarten Dijker sells the mushrooms to renowned restaurants on and off Texel. Shiitake mushrooms are healthy since they lower cholesterol and blood pressure. It is rich of vitamin B12, which makes it an ideal substitute for meat (Texelse Paddestoelenkwekerij, 2011). Shiitake mushrooms can be kept in the refrigerator for one to two weeks.

Since Maarten Dijker has not been interviewed yet, it is hard to estimate what drives him to convince him to join the project. However based on background information some assumptions can be made on what might be attractive for Texelse Paddenstoelenkwekerij. For example it can be assumed that Maarten Dijker is interested in energy effective solutions. An article indicates that Maarten Dijker has bought an energy sufficient refrigerator, since he believes it is an investment that saves costs in energy on the long term. In this article Maarten Dijker tells that he had visited a meeting by Stichting Duurzaam Texel, indicating he is interested in sustainable cultivation (SenterNovem, unknown).

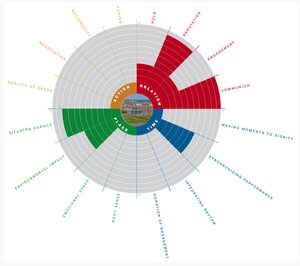

Figure 5.8 YUPTA of the Texelse Paddenstoelenkwekerij regarding mushroom cultivation on coffee waste

The role of Maarten Dijker in the system for using coffee waste is quite important, however since Maarten Dijker already supplies shiitake mushrooms with a more traditional method. Since Maarten Dijker is often mentioned in culinary fairs for local food production and offers tours as a tourist attraction, reputation seems to be very important for Maarten Dijker to sell shiitake mushrooms.

The first notification of the typical Texel last name ‘Dijker’ comes from a source of 1609 (Miriam, 2001). It could be possible that Maarten Dijker descends from a family which has a long history on the island of Texel. This could mean that Maarten Dijker attaches a lot of value to Texel culture and wants Texel to become self-supportive. However since in an article Maarten Dijker mentions costs savings as the main reason for buying energy sufficient refrigerators, a self-supportive Texel might have a lower priority than cost savings. Since growing mushrooms requires not much action during cultivation, engagement is not estimated high.

Synchronizing performance with the hospitality industry and integrating rhythm however is important. Texelse Paddenstoelenkwekerij needs fresh spent coffee, while the hospitality industry needs the shiitake mushrooms to prepare the dishes for the day. The exchange of resources could happen in the morning.

The environmental impact is very important to Maarten Dijker, since creating the right environment is vital for the mushrooms to grow. The quality of how Maarten Dijker creates the environment, determines the quality of the mushroom harvest. Since Maarten Dijker lives from cultivating mushrooms, respiratory is estimated high. Tuning is important to build a relationship with restaurants to make sure both stakeholders can rely on each other to deliver a constant resource stream for production.

Hospitality industry

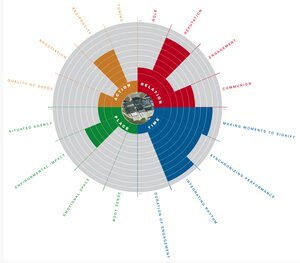

The role of the restaurants is important, since they have to deliver the coffee residual. Since reputation is important, restaurants can attract visitors by promoting it uses biological produced shiitake mushrooms cultivated on waste. Restaurants have to be engaged to create a more self-supportive sustainable Texel by closing bio-cycles. The values of the YUPTA cycle concering time are the same for the restaurant as Maarten Dijker, since both are dependent on each other.

Although the restaurants have to give the coffee waste to Maarten Dijker, they do not transform the coffee waste into a valuable resource. Therefore environmental impact is estimated lower. The quality of deeds however is important, since the fresh coffee spent has to have little contamination of molds. It is therefore important that restaurants handle the coffee waste hygienically. The more hygienic they handle the coffee waste, the larger the shiitake mushroom harvest.

Figure 5.9 YUPTA of the hospitality industry with regards to mushroom cultivation on coffee waste.

Identified Needs:

Estimation available coffee waste

According to Gro Holland 80000 ton coffee residual is wasted every year in the Netherlands (Gro Holland, 2014). On 14 December 2014 the Netherlands counted 16910968 inhabitants. This means that yearly 4.73 kg of coffee waste is generated per habitant. On 1 November 2014 there were 13597 inhabitants on Texel, meaning they generate 64313 kg of coffee waste a year.This results in 13g of coffee waste a day. Yearly 800.000 visitors visit Texel (Ecomare, 2014). Assuming they visit Texel for one day, this leads to an additional 1040 kg of coffee waste. This leads to a total amount of 65353 kg coffee waste a year. Since some visitors may visit Texel for more days, this amount is likely to be larger.

Assuming you use the coffee waste for shiitake mushrooms (ratio 0.3 to 0.5 per 1kg coffee waste), it means you can deliver 19606 kg to 32676 kg of shiitake mushrooms a year. Currently the Texelse Paddestoelenkwekerij delivers to 13 restaurants, resulting in 1508 kg to 2513 kg which can be sold to each of them yearly. Daily this means there is 4.1 kg to 6.9 kg available for each restaurant. If you need 150 gr of shiitake mushrooms for each menu you can serve 27 to 46 dishes a day. In case this is not sufficient the traditional method of cultivation by Texelse Paddenstoelenkwekerij can be used as well. Shiitake mushrooms that become wasted can be composted again. The advantage for the Texelse Paddenstoelenkwekerij is that cultivation on coffee waste is cheaper since sterilization is not necessary when you use fresh coffee spent. The cultivation on coffee spent can attract more tourists for the tours Maarten Dijker organizes in his company, which results in higher income.

Actions needed by stakeholders

In this scenario both actors become depended on each other, since waste of the hospitality industry becomes a resource for the hospitality industry again through the Texelse Paddenstoelenkwekerij as an intermediary. Since the hospitality industry benefits from shiitake cultivation and the coffee waste is wasted anyway, the hospitality industry can give the coffee waste to Texelse Paddenstoelenkwekerij for free. This could make the deal interesting for Maarten Dijker, since production cost are lowered since the sterilization process is not necessary when using the free coffee spent.

Maarten Dijker already supplies the hospitality industry with shiitake mushrooms, meaning there is already transport available. To collect the coffee waste it is the easiest to use the existing delivery moments of the shiitake mushrooms. Through this method Maarten Dijker and the hospitality industry are able to increase shiitake mushroom production on a costs effective sustainable manner.

5.3.4 Biodigester

Technology of the biodigester:

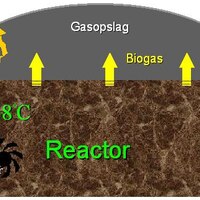

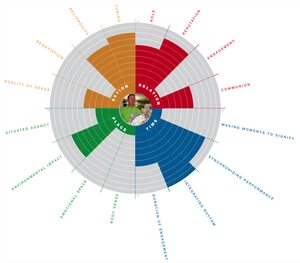

Anaerobic digestion in a biodigester is a process by which microorganisms break down biodegradable materials without the presence of oxygen. The purpose of this process is twofold: to manage waste and/or to produce fuels (Climate Gate, 2012).

A biodigester gives two products as output: biogas and fertilizer. The biogas can be used as an energy source in different industries. The fertilizer can be used in for instance the aquaculture and it can go back to the farms. The input of bio-digester consists of biomass. This is often mainly manure, but can also be other organic products such as vegetable and fruit waste. The products that may be used in Dutch biodigesters are listed in the ‘white list’ (which is defined by the government).

Biodigesters vary from very small systems in private gardens to very large installations on plants. The figure below shows the main components of the system.

Figure 5.10 A biodigester and its simplified processes

Biodigesters in the Netherlands

In 2012, 232 bio-digesters were located in the Netherlands (see figure 5.11). These installations need huge amounts of biomass, thus manure and co-products. The supply to the Dutch biodigesters is decreasing since a lot of it is transported to Germany. In Germany over 5000 biodigesters are located that together have a huge demand of biomass. Because of the German and France competitors, the price of Dutch biomass is high and this makes it hard for Dutch biodigesters to stay affordable (Ypma, 2011). As the picture below shows, on Texel there is no biodigester located yet.

Figure 5.11 Biodigesters in the Netherlands

Actor analysis:

The key players needed to set up a biodigester company are of course the suppliers of biomass and the operator of the biodigester. However, it would be shortsighted to only look at these two actors. Building a biodigester would have a large impact on the island and its residents. It would influence the landscape and people might be afraid of the reek it might bring. The rules and regulations that concern the biodigester are made on a national level. Therefore the actor analysis below includes the biodigester company, the suppliers, the municipality, the residents and the national government.

The biodigester company

Biodigesters can be owned by a private company (link), but often it is exploited by a group of farmers (for instance:link) . Together they can share the financial risks and produce a lot of manure and co-products. Owning a biodigester has two main advantages for farmers: it is a way to manage their manure and they can use the output (fertilizer) for their fields. Also, they can use the energy (biogas) for their greenhouses for example.

Farmers are definitely present on Texel: agriculture is dominating the landscape. Half of the island is in use for crops, cattle farms and horticulture farms. 15% of the working population on Texel works in these industries. About 175 farms are located on the island. They own about 4500 ha grassland, 4000 ha of crops and 500 ha horticulture (Boerenklasse). The cattle farms are often small and extensive. The farms have cows (for milk production and/or meat production) and almost 14,000 sheep.

A collective of farmers that together exploit the biodigester seems the best solution. The illustration below shows the needs of such a collective. In such a collective negotiation and tuning is very important. The farmers have to trust each other and communicate with each other often. Therefore are also engagement and communion important. Time is the most dominant aspect of the needs of the collective. It is important that the farmers integrate the bio-digester into the rhythm and see it is a durable engagement.

Figure 5.12 YUPTA Analysis of an biodigester that is exploited by a group of farmers

Suppliers of biomass

The most important suppliers for the biodigester are ofcourse the farmers. The biomass will come from agriculture, cattle breedings and mushroom cultivation. The interrelations are displayed in the illustration of the future design. The operator of the biodigister will pay the suppliers for the biomass (unless the operator is the supplier ofcouse). It is important that the supplied biomass is purely organic and biodagrable and that the materials are on the ‘white list’.

Dutch government

Currently, biodigesters in the Netherlands cannot exist without subsidies.

Biodigester installations qualify for the Milieukwaliteit Electriciteit Productie (MEP) subsidy and the Energie-investeringsaftrek (EIA) which can save coorporation tax (in Dutch: vennootschapbelasting).

However, these subsidies are often too low and uncertain for entrepreneurs to take the risk of building a biodigester. Besides, the white list (that says which products may be used in the biodigester) is too limited. Products such as coffee waste are seen as garbage and are not aloud as input for a biodigester. Most Dutch biodigesters are not profitable due to these causes. Biodigesters in surrounding countries such as France and Germany have a longer white list and therefore outcompete Dutch biodigesters. It is important for the implementation of a biodigester on Texel that the white list is extended and that the subsidies give certainty to the future operator of the biodigester.

The municipality of Texel

To build a biodigester, several licenses are required. The municipality claims that they want a sustainable and energy independent island. Since a biodigester would contribute to that ideal, the municipality has to support the implementation and should give the right licenses. It would also be the task of the municipality to inform local residents.

Local residents

It happened before that local residents stopped the construction of a biodigester by protesting against it (seehttp://www.deweekkrant.nl/pages.php?page=436680). Neighbors can be concerned about the environmental impact of the biodigester without knowing that the particulates of a highway are much more dangerous for health and that biodigesters decrease the emissions of the manure. It is the task of the municipality to inform the local residents about the advantages and it is the task of the operators of biodigesters to be transparant.

Identified Needs:

To successfully implement a bio-digester on Texel, several actions need to be taken first. Farmers should form a collective that wants to exploit the biodigester. The size of the collective can vary between 5 and 40 farmers. The collective has collect enough money (also with subsidies) to build a biodigester. It is also important that they have good contacts and contract with other biomass suppliers (for example with Maarten Dijker of the mushroom cultivation). The municipality has to give the right permissions for the construction of the biodigester. Besides, the municipality has the task to inform local residents and in this way try to prevent protests. On the higher governmental level it is important that the white list gets extended with the types of biomass present on the island. In that way, also suppliers of for example coffee waste can join.

5.3.5 New Transport system

Technology:

To become a sustainable island, Texel needs to change its current sub-system of Materials and waste. In the proposed design there will be the need of moving waste streams within its new neurons-like network. Waste will not be considered anymore as waste, but as food, to be fed into another part of this sustainable chain. One of the new technologies to be introduced on the island is the transportation of these waste streams.

The exchange of waste and food will be needed in a daily schedule and the transport of waste and food will take place everyday.

For a sustainable island, also the transport is expected to be sustainable and economically feasible. Normal transport systems have bad fuel efficiency and high co2 emissions, due to the use of fossil fuel to power vehicles. A sustainable transport system has positive effects on environmental, societal and economic sustainability of the communities they serve.

The technology proposed is a biofuel-powered transport system. If we consider the expectations of biofuel production of the bio-digester that is embedded in the new sub-system, it is wise to consider the use of part of the biofuel to power the waste and food transport system within the island.

Part of the biofuel produced by the bio-digester will be moved to a transport facility center (HVC). Biofuels such as ethanol and bio-diesel have the potential of decreasing the greenhouse gas emissions that would take place if normal fossil fuels will be used to power the new transport system. (Hunt, 2006)

Actor analysis:

Two key actors are relevant for this subsystem: HVC and the municipality. These are described below.

HVC

As already explained before, HVC is the company working on the island for the management and transport of waste for landfill, recycling and incineration. The company will be cooperating with the municipality to provide the actors involved in the new sub-system with the waste streams and food needed. Schedules for the food and waste transport will be studied together with all the other actors involved, in order to find a balance in the synchronization of performances, which is vital for the new transport system to work.

Figure 5.13 YUPTA analysis of HVC with regard to a new transport system

Municipality

The Municipality of Texel will have a central role in the organization of this new transport system. It will move investments and efforts to achieve a sustainable way of transporting the waste streams, together with HVC. Well-organized schedules will be embedded and will serve as a frame for HVC to move within the network.

Figure 5.14 YUPTA analysis of the Municipality with regards to the new transport system.

Identified Needs:

This part of the subsystem requires many interventions and high investments. New equipment (trucks) are needed which is expensive. Besides, the current system (in terms of schedules, rules and laws) needs to be adapted in order to fulfill the future needs in the subsystem.